Elke minuut, elk uur, elke dag: Halffabricaten op niveau bij Meijer Metal

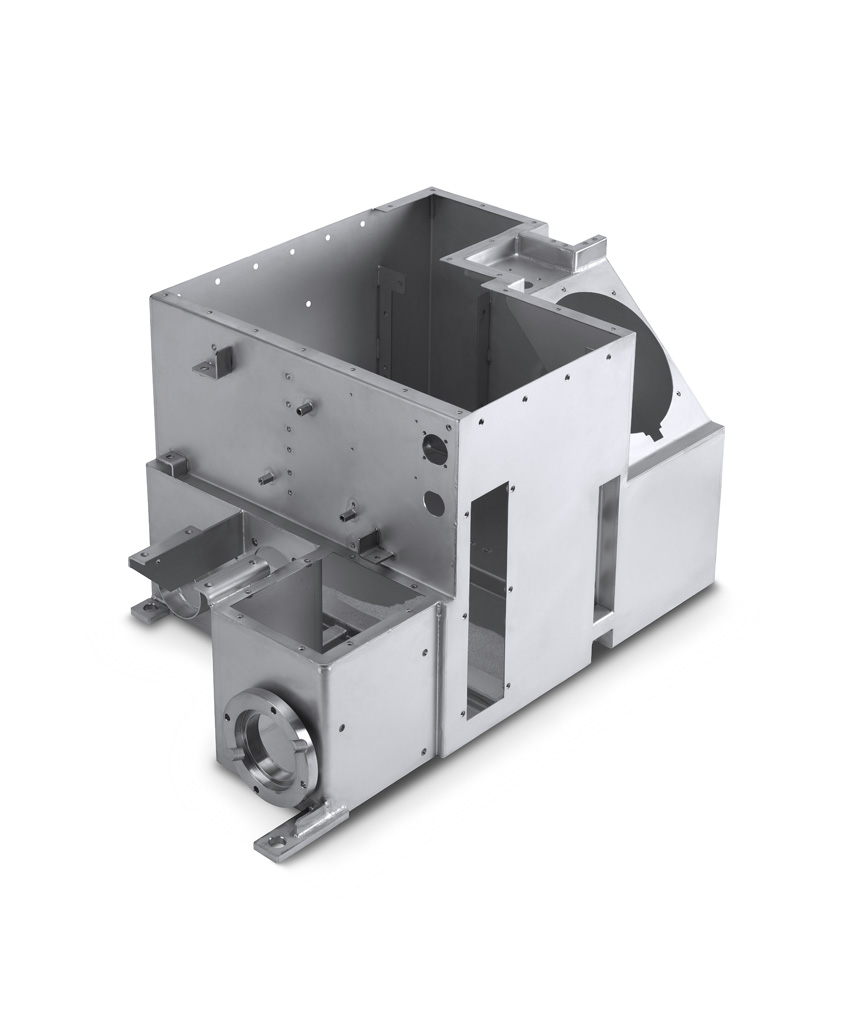

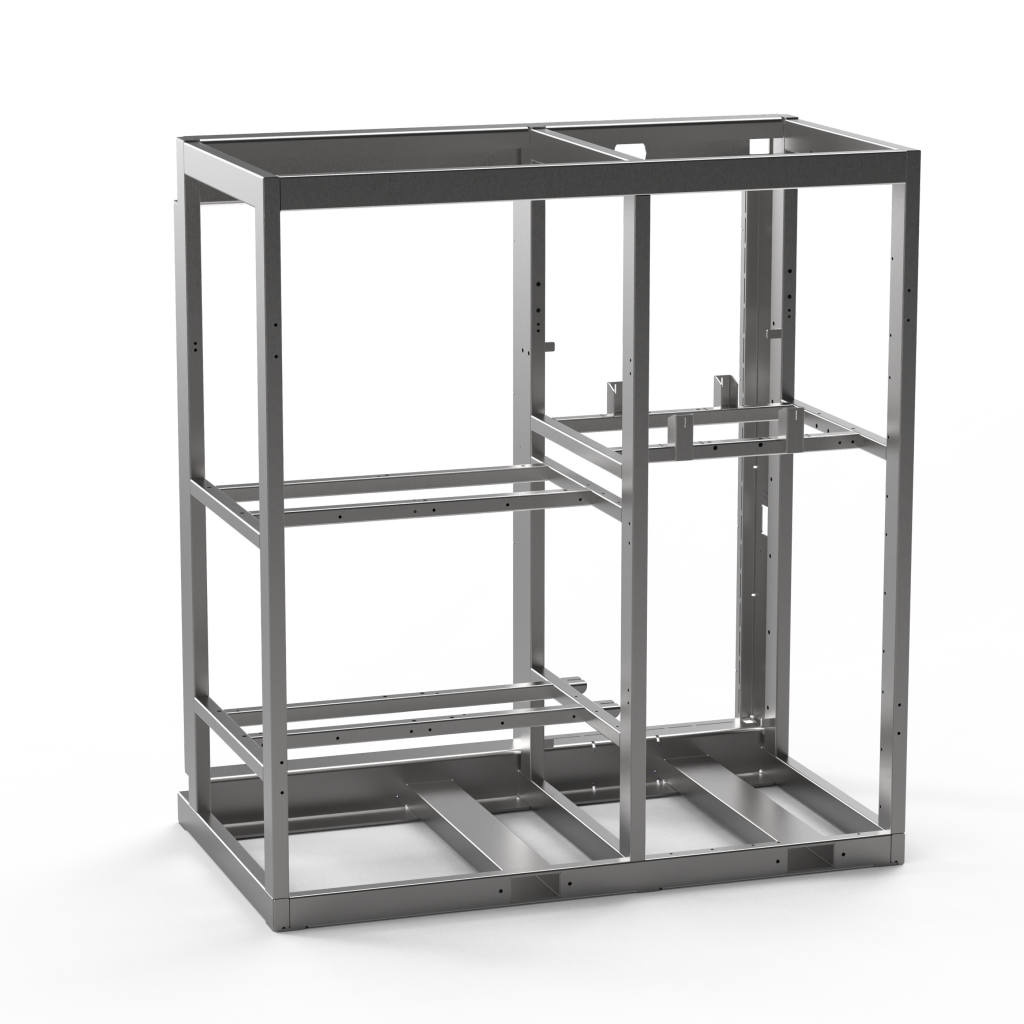

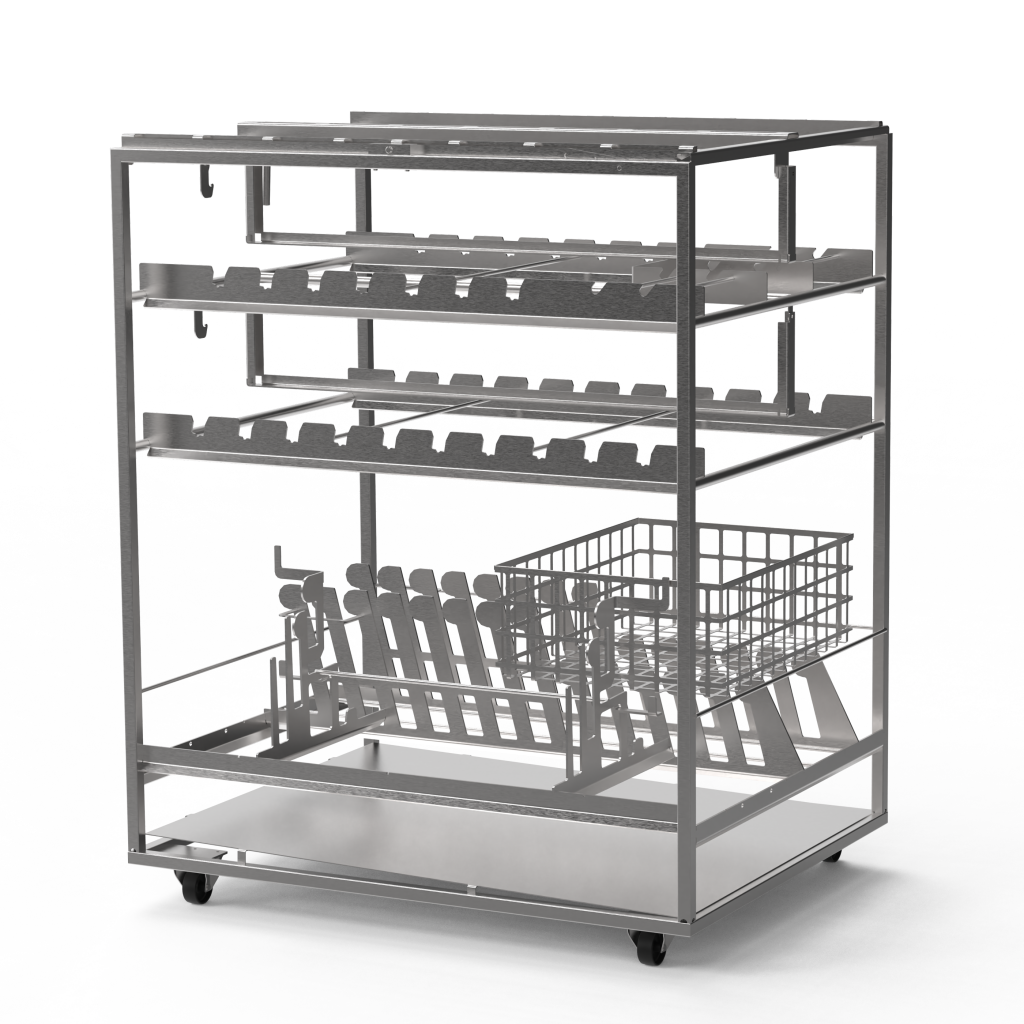

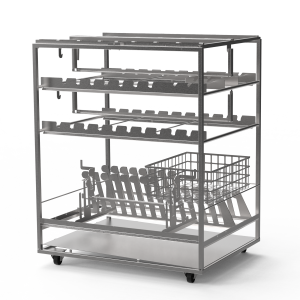

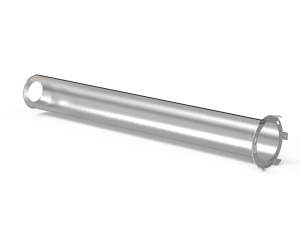

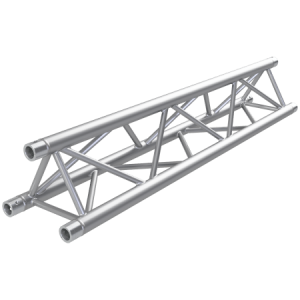

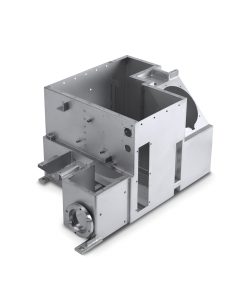

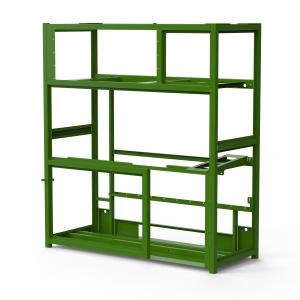

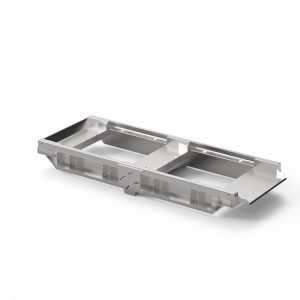

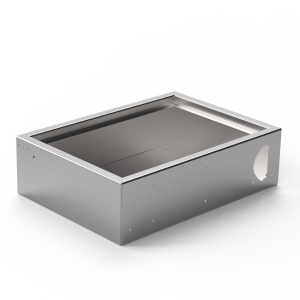

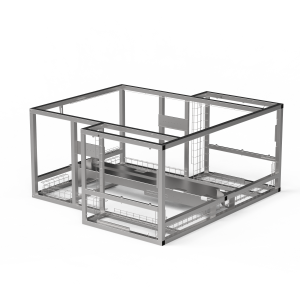

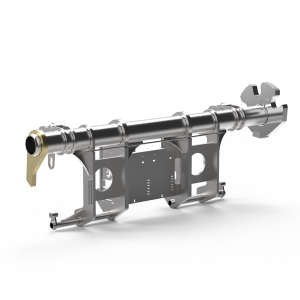

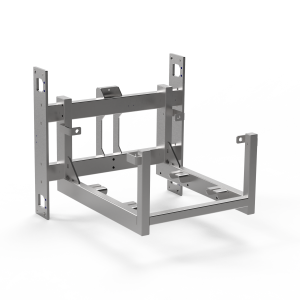

Bij Meijer Metal 𝗽𝗿𝗼𝗱𝘂𝗰𝗲𝗿𝗲𝗻 we dagelijks een 𝗯𝗿𝗲𝗲𝗱 𝘀𝗰𝗮𝗹𝗮 aan 𝗵𝗮𝗹𝗳𝗳𝗮𝗯𝗿𝗶𝗰𝗮𝘁𝗲𝗻. Dit realiseren we met een uitgebreid en geavanceerd machinepark, bestaande uit 𝗹𝗮𝘀-, 𝗳𝗿𝗲𝗲𝘀- 𝗲𝗻 𝗸𝗮𝗻𝘁𝗿𝗼𝗯𝗼𝘁𝘀, én 𝘀𝘂𝗽𝗲𝗿𝘀𝗻𝗲𝗹𝗹𝗲 𝗽𝗹𝗮𝗮𝘁𝗹𝗮𝘀𝗲𝗿𝘀 die met hoge precisie en snelheid zowel grote als kleine producten snijden. Onze 𝗯𝘂𝗶𝗴𝘀𝘁𝗿𝗮𝗮𝘁 telt maar liefst 𝟭𝟰 𝗸𝗮𝗻𝘁𝗯𝗮𝗻𝗸𝗲𝗻, die razendsnel worden omgesteld voor efficiënt en […]

Lees meer